Infrastructures

Clean Rooms

The Department has three clean rooms (Class 100) that allow processes to be carried out in a controlled environment.

The Department has three clean rooms (Class 100) that allow processes to be carried out in a controlled environment.

CR1: Activities carried out in the first clean room (CR1) primarily involve the production of nanostructured powders through chemical synthesis (sol-gel, hydrothermal) and their use as functional materials for the production of sensing films. Two chemical hoods and four extractor cabinets are available for reagents storage. The semiconductor powders, synthesized and heat-treated (Lenton ECF 12/6 muffle furnace), are used to prepare screen-printing pastes, which are deposited as thick films on suitable substrates (screen printer (Aurel C920, Scent Srl). These are then packaged in the Sensors Laboratory to finalize the chemoresistive gas sensor.

Contacts: Prof. Cesare Malagù - Dr. Barbara Fabbri

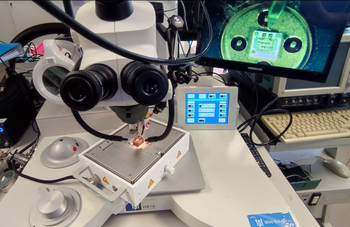

CR2: In CR2, high-precision characterizations are performed on crystals used in particle physics experiments, in particle accelerators such as the LHC to deflect beams, and in synchrotrons and X-FELs as innovative optics. Two high-resolution diffractometers allow investigation of the crystallographic quality and curvature of the crystals. Furthermore, an infrared interferometer measures the thickness of the samples with micrometer resolution. A high-vacuum oven allows thermal testing of the samples in a controlled environment. Recently, a robotic arm has been introduced for the assembly of samples and systems that They require greater delicacy and precision, as well as innovative solutions..

Contacts: Dr. Andrea Mazzolari - Dr. Marco Romagnoni

CR3: The hoods send a further filtered airflow, ensuring an additional level of cleanliness during the most delicate semiconductor etching and lithography phases. A megasonic tank allows the removal of the smallest particles from the substrates before subsequent processing. Plasma-assisted chemical vapor deposition (CVD) is also performed. Germanium films can be produced, used as an active layer for aerospace applications. These films can be used in thermovoltaics, which converts infrared radiation emitted by heated bodies into incandescence.

Contacts: Prof. Donato Vincenzi - Dr.. Andrea Mazzolari

Block G, ground floor.

Electrical shop

The electronics shop provides design, prototyping, development, and installation of components, electronic boards, and data acquisition systems to support experiments and research projects involving the Department of Physics and Earth Sciences of the University of Ferrara and the INFN Ferrara Section, and at international facilities such as CERN, J-Lab, IHEP, and the Stanford Underground Research Facility.

The electronics shop provides design, prototyping, development, and installation of components, electronic boards, and data acquisition systems to support experiments and research projects involving the Department of Physics and Earth Sciences of the University of Ferrara and the INFN Ferrara Section, and at international facilities such as CERN, J-Lab, IHEP, and the Stanford Underground Research Facility.

Design, prototyping, and testing are performed using the following equipment:

- PCs and workstations for CAD design, including circuit diagrams, circuit board layout, simulations for signal and power integrity analysis, and the development of digital systems based on Field Programmable Gate Arrays (FPGAs).

- LPKF ProtoMat S103 micro-milling machine for rapid development of printed circuit board prototypes.

- ITRONIK MINILAB vapor-phase technology oven for small-series SMD assembly.

- WeissTechnik LabEvent L C/64/40/3 climate chamber.

- TPT HB16 semi-automatic thermosonic wire bonder for (Al) wedge – (Au) ball & bump bonding.

- High-performance signal generators:

- Keysight M8190A Arbitrary Waveform Generator: dual channel 12-bit, 12 GS/s.

- Active Technologies PG1072 – HW rev. B, 70ps rise time

- Oscilloscopes with up to 12-bit HW resolution and analog bandwidths up to 12GHz

- LeCroy 40GHz Wavepulser-40IX-BUNDLE TDR/TDT impedance analyzer

Block C, room C112

Contacts: Eng. Angelo Cotta Ramusino

High Performance Computing Laboratory - HPC

The High Performance Computing (HPC) laboratory designs, implements, optimizes, and evaluates numerical simulation algorithms in the field of theoretical and experimental computational physics for highly parallel computing systems, also known as HPC systems. It also conducts research in the following areas: parallel and distributed programming models; modeling and performance measurement of HPC systems; and the use of accelerators such as GPUs and FPGAs to increase the performance of scientific and deep learning applications. The HPC laboratory includes the COKA computing cluster, a system based on heterogeneous nodes composed of multicore CPUs and GPUs interconnected via a high-speed network. The current version of the system has a peak performance of approximately 100 TFLOPs and comprises four computing nodes, each equipped with two 8-core Intel Xeon CPUs and eight NVIDIA K80 dual-GPU accelerator cards, and 512 GB of RAM, interconnected via an Infiniband network.

The High Performance Computing (HPC) laboratory designs, implements, optimizes, and evaluates numerical simulation algorithms in the field of theoretical and experimental computational physics for highly parallel computing systems, also known as HPC systems. It also conducts research in the following areas: parallel and distributed programming models; modeling and performance measurement of HPC systems; and the use of accelerators such as GPUs and FPGAs to increase the performance of scientific and deep learning applications. The HPC laboratory includes the COKA computing cluster, a system based on heterogeneous nodes composed of multicore CPUs and GPUs interconnected via a high-speed network. The current version of the system has a peak performance of approximately 100 TFLOPs and comprises four computing nodes, each equipped with two 8-core Intel Xeon CPUs and eight NVIDIA K80 dual-GPU accelerator cards, and 512 GB of RAM, interconnected via an Infiniband network.

Referenti: Dott. Enrico Calore - Prof. Fabio Sebastiano Schifano

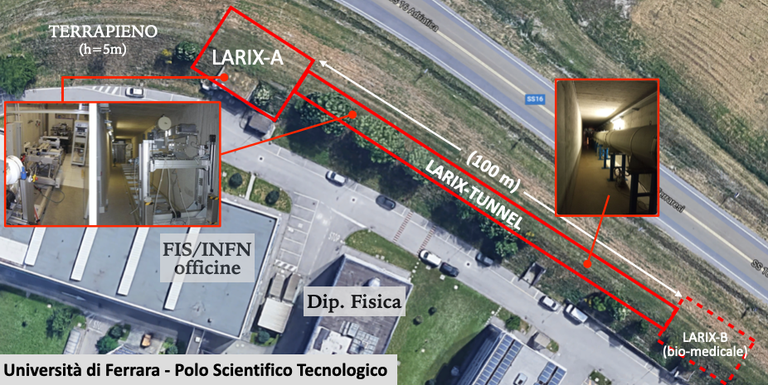

LARge Italian X-ray facility - LARIX

LARIX is a multidisciplinary laboratory suitable for data engineering, X-ray diagnostics, detector calibration, and crystallography. Three main research groups work at the facility: the Medical Physics group, the Archaeometry group, and the High Energy Astrophysics (AAE) group. The LARIX laboratory is supported by the University of Ferrara, the National Institute for Nuclear Physics (INFN), and the Italian Space Agency (ASI) and consists of three sections: LARIX-A, LARIX-T, and LARIX-B.

LARIX is a multidisciplinary laboratory suitable for data engineering, X-ray diagnostics, detector calibration, and crystallography. Three main research groups work at the facility: the Medical Physics group, the Archaeometry group, and the High Energy Astrophysics (AAE) group. The LARIX laboratory is supported by the University of Ferrara, the National Institute for Nuclear Physics (INFN), and the Italian Space Agency (ASI) and consists of three sections: LARIX-A, LARIX-T, and LARIX-B.

Two beamlines are used for AAE activities: one is installed at LARIX-A and is equipped with a fixed-output Bragg-Bragg monochromator, while the second is installed inside the 100-m tunnel of LARIX-T and can provide a low-divergence polychromatic gamma-ray beam. These facilities are used to test hard X-ray detectors, perform ground-based calibrations of X-ray astronomy instruments, and test samples that deflect high-energy radiation.

At LARIX-A, three other beam lines are active for applications on X-ray imaging and characterization of biomedical samples, on natural sciences, or on cultural heritage. These include a high-resolution microtomography beam line, a beam line for the production of quasi-monochromatic X-ray radiation with an energy range of 10 to 35 keV, and a beam line for multi-purpose planar imaging, also used for educational purposes. At LARIX-B, a scanner (also transportable in situ) is installed for high-resolution radiography of large-scale works of art.

Contacts

Prof. Piero Rosati - Astrophysics

Prof. Angelo Taibi - Medical Physics and Archaeometry

Local Microseismic Network - NetFER

Net4Fer (Seismic Network for Ferrara) represents an important infrastructure of our Department, serving the territory, particularly the city of Ferrara. The network consists of 15 strategically distributed stations within a 12 km radius of the Casaglia geothermal field: 5 belong to the old network, 7 are newly established, and 3 are still under completion.

-

Old Stations: These are equipped with single-component seismometers installed in boreholes (except for one station, which has a three-component seismometer), at depths ranging from 12 to 57 meters.

-

Newer Stations: The 10 more recent stations are all equipped with three-component instruments: a 1 Hz seismometer installed at 150 meters depth in a borehole, and an accelerometer positioned at 2 meters above the ground.

-

Central Station: This station has a broadband seismometer with a 30-second period.

-

Additional Equipment: Two sites are also equipped with GNSS (Global Navigation Satellite System) receivers to monitor ground deformations, while at the reinjection well of the geothermal fluid, a digital manometer continuously measures pore pressure.

All sensor data is transmitted in real-time to the Seismic Room's servers, where it is automatically analyzed. This setup enables continuous seismic monitoring, allowing for the immediate detection and reporting of any anomalies.

This network plays a vital role in monitoring seismic activity in the region, particularly in relation to the Casaglia geothermal field, ensuring early detection of seismic events or anomalies and supporting geotechnical safety and environmental management.

Building B, Room B210

Contact person: Dott. Fabio Brighetti

Mechanical shop

The mechanical shop is composed of six different departments: precision machining, carpentry and heat treatment, sheet metal working, quality control, additive manufacturing, CNC programming, and finally a metal and small parts warehouse.

Precision machining department: 5-axis CNC milling machine – CB Ferrari A15, 4-axis CNC milling machine – Bridgeport 700X, 3-axis CNC milling machine – Deckel, CNC lathe – Gildemeister, parallel lathe, wire-cut EDM – AGE, column drills, radial drill – Bergonzi, drill/mill, surface grinder with magnetic base, vertical (Opus) and horizontal (Pedrazzoli) band saw, sharpening and polishing wheels, sharpener for twist drills and HSS tools, sanding/chamfering machine for deburring.

Carpentry and Heat Treatment Department: Manual and automatic TIG welding system, arc welding, brazing, Unitek 250 DP spot welder, plasma cutting, 220V continuous wire welder, protective atmosphere heat treatment furnace, hydraulic press, sandblasting machine.

Sheet Metal Working Department: Waterjet, circular saw squaring machine, manual bending machine.

Quality Control Department: Poli Sky VI CNC 3D measuring center

Additive Manufacturing Department: STRATASYS FDM 3D printer, ultrasonic cleaning tank, vacuum packaging system.

Block G, ground floor.

Contact: Eng. Alessandro Saputi